Table of Contents

- Understanding UV Printing

- Metallic Cardboard Explained

- The Science Behind UV Print on Metallic Cardboard

- Aesthetic Appeal: Enhancing Visual Impact

- Durability and Longevity of UV Prints on Metallic Cardboard

- Sustainability Benefits of UV Print on Metallic Cardboard

- Branding and Marketing Advantages

- Cost Efficiency of Using UV Print on Metallic Cardboard

- Customization Possibilities with UV Print on Metallic Cardboard

- UV Print on Metallic Cardboard for Different Industries

- Challenges and Considerations in UV Printing on Metallic Cardboard

- Steps to Get Started with UV Print on Metallic Cardboard

- Future Trends in UV Printing on Metallic Cardboard

- Case Studies: Success Stories with UV Print on Metallic Cardboard

- Customer Perception and UV Print on Metallic Cardboard

- Integrating UV Print into Your Packaging Strategy

- Common Misconceptions About UV Print on Metallic Cardboard

- Expert Tips for Maximizing the Benefits of UV Print on Metallic Cardboard

- Conclusion

Packaging has come a long way from its humble beginnings as a simple means to protect goods. Over the centuries, packaging has evolved into a sophisticated tool for branding, marketing, and consumer engagement. Today, it is not merely about safeguarding the product; it's about creating a memorable experience, a visual and tactile connection between the brand and the consumer. At the heart of this evolution lies the role of printing, which has transformed packaging from basic to brilliant.

In recent years, UV printing has emerged as a frontrunner in the packaging industry, particularly in enhancing the appeal and functionality of metallic cardboard. UV printing, or ultraviolet printing, is becoming increasingly popular for its ability to produce vibrant colors, intricate details, and durable finishes. This article will explore how UV printing on metallic cardboard boosts packaging, offering a compelling combination of aesthetics, durability, sustainability, and cost-efficiency.

Understanding UV Printing

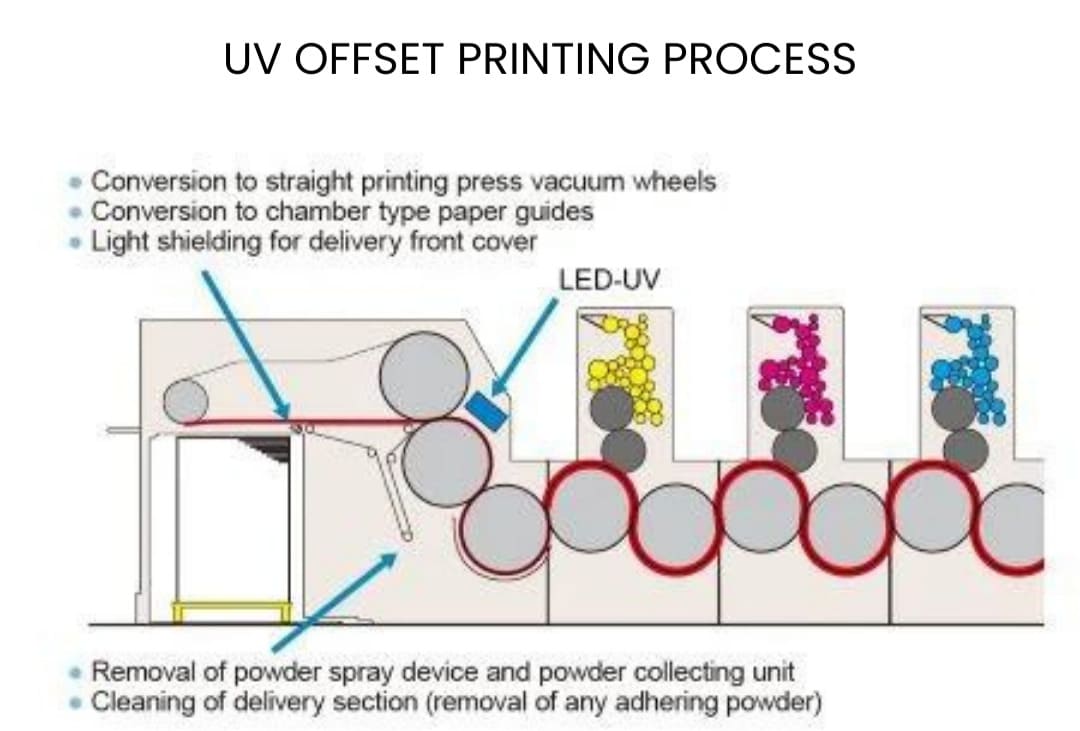

UV printing is a modern printing technique that utilizes ultraviolet light to cure or dry ink instantly as it is printed. This process ensures that the ink adheres firmly to the surface of the material, resulting in sharp, vivid prints that are resistant to smudging and fading. The magic happens when the UV light hits the specially formulated UV inks, causing a photochemical reaction that hardens the ink almost instantly.

This quick-drying process not only improves the print quality but also allows for printing on a wide range of materials, including non-porous surfaces like plastic, glass, and metallic cardboard. Unlike traditional printing methods, which may require time for the ink to set or dry, UV printing eliminates this wait time, enhancing productivity and reducing production costs. The advantages of UV printing over traditional methods are numerous, including better color accuracy, higher durability, and the ability to print on diverse substrates.

Metallic Cardboard Explained

Metallic cardboard is a type of packaging material that combines the sturdy, protective qualities of cardboard with a shiny, reflective metallic finish. This finish can be achieved through various processes, such as laminating metallic foils onto the cardboard or coating it with metallic inks. The result is a visually striking material that catches the light and captures the attention of consumers, making it a popular choice for luxury packaging. To learn more about this unique material, check out our comprehensive guide on Metalized Cardboard Stock.

What sets metallic cardboard apart is its unique combination of durability and aesthetics. The metallic finish not only enhances the visual appeal of the packaging but also adds an extra layer of protection, making it resistant to moisture and wear. Common uses of metallic cardboard in the packaging industry include high-end cosmetics packaging, electronics, food and beverage, and premium retail products. Its ability to convey luxury and quality makes it a favored material for brands looking to make a statement.

The Science Behind UV Print on Metallic Cardboard

The process of UV printing on metallic cardboard is a fascinating interplay of science and technology. When UV ink is applied to the metallic surface, the ultraviolet light triggers a rapid curing process that bonds the ink to the substrate. This bonding is crucial because metallic surfaces are typically non-porous, meaning they do not absorb ink like traditional paper or cardboard. The UV light ensures that the ink adheres properly, creating a durable and vibrant print that stands out against the shiny background.

The role of UV light in curing inks on metallic cardboard cannot be overstated. It is this precise exposure to UV light that solidifies the ink instantly, preventing it from spreading or smearing. This precision is why UV inks work better on metallic surfaces than traditional inks, which may not adhere well or could result in dull, less vibrant prints. UV printing provides the perfect solution for achieving high-quality prints on metallic cardboard, combining the best of both worlds: the brilliance of metallic finishes and the durability of UV inks.

Aesthetic Appeal: Enhancing Visual Impact

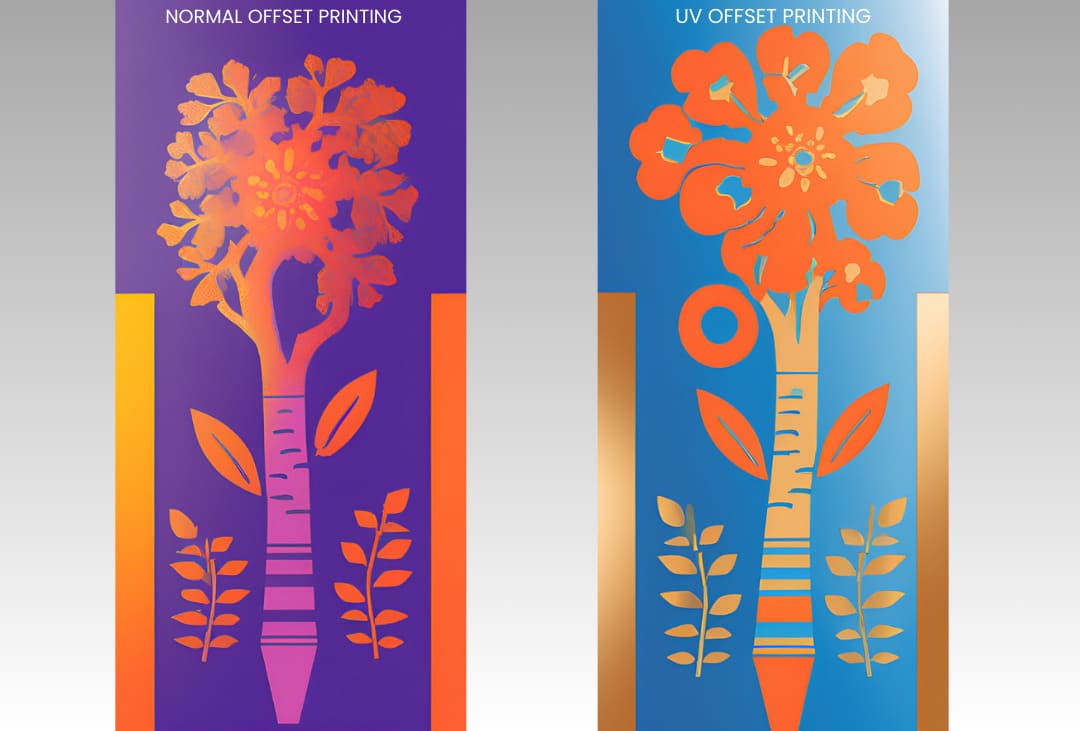

One of the most compelling reasons to use UV print on metallic cardboard is the unparalleled aesthetic appeal it offers. The combination of UV printing and metallic cardboard produces vibrant colors that pop and capture attention. The metallic surface acts like a mirror, reflecting light and making the colors appear even more vivid. This effect can be used to create eye-catching packaging that stands out on store shelves and attracts consumers.

Metallic finishes add depth and luxury to packaging, giving products a premium feel that is associated with high quality and exclusivity. This is particularly important in industries like cosmetics and electronics, where first impressions are crucial. A well-designed package with a metallic finish can convey a sense of sophistication and elegance, enhancing the perceived value of the product inside.

Real-world examples of eye-catching designs using UV print on metallic cardboard are plentiful. For instance, luxury beauty brands often use metallic packaging with UV-printed floral patterns or intricate designs that reflect the light and catch the eye. Beverage companies use UV-printed metallic labels to create stunning effects that make their bottles shimmer and stand out in a crowded market.

Durability and Longevity of UV Prints on Metallic Cardboard

Beyond aesthetics, UV printing on metallic cardboard offers superior durability and longevity, making it an excellent choice for packaging that needs to withstand the rigors of transportation and handling. UV-printed packaging is resistant to fading, even when exposed to sunlight, thanks to the rapid curing process that locks the colors in place. This resistance to UV light ensures that the prints remain vibrant and clear for longer periods.

Moreover, UV-printed metallic cardboard is highly resistant to scratching and moisture. The cured ink forms a protective layer that guards against abrasions and spills, ensuring that the packaging maintains its pristine appearance from the point of manufacture to the consumer's hands. This enhanced durability extends the lifespan of metallic cardboard packaging, reducing the need for frequent replacements and contributing to overall cost savings.

Sustainability Benefits of UV Print on Metallic Cardboard

In an era where sustainability is at the forefront of consumer concerns, UV printing on metallic cardboard offers several eco-friendly benefits. Unlike traditional printing methods that may require solvents and emit volatile organic compounds (VOCs), UV printing produces less waste and fewer emissions. The UV curing process is more efficient, reducing the amount of energy needed for drying and minimizing the environmental footprint of the printing process.

Additionally, metallic cardboard with UV print is recyclable, provided that the metallic layer is thin and can be separated from the cardboard during the recycling process. This recyclability aligns with the growing consumer demand for sustainable packaging options, allowing brands to appeal to eco-conscious consumers while maintaining a high-quality appearance. To learn more about the future of sustainable packaging and the challenges and innovations driving the industry forward, check out our blog on The Future of Sustainable Packaging: Innovations and Challenges.

Branding and Marketing Advantages

UV printing on metallic cardboard provides significant branding and marketing advantages, elevating brand perception and creating a memorable unboxing experience. The luxurious look and feel of metallic cardboard combined with the vivid colors of UV print can enhance a brand's image, making it appear more premium and sophisticated. This perception is crucial in markets where consumers are willing to pay more for products that look high-end.

Creating a premium unboxing experience with UV-printed metallic packaging can also foster customer loyalty. When consumers receive a beautifully packaged product, they are more likely to share their experience on social media, generating free marketing for the brand. In a competitive market, UV print on metallic cardboard can help differentiate a brand from its competitors, making products more appealing and driving sales.

Cost Efficiency of Using UV Print on Metallic Cardboard

While UV printing on metallic cardboard may have higher upfront costs compared to traditional printing methods, it offers significant cost efficiencies in the long run. The durability of UV-printed packaging reduces the need for frequent replacements, saving brands money over time. Additionally, the quick curing process of UV printing increases production speeds, lowering labor costs and enhancing overall efficiency.

Long-term savings through durability and less waste make UV printing a cost-effective choice for brands. By investing in UV print on metallic cardboard, companies can reduce their environmental impact, appeal to sustainability-minded consumers, and enhance their brand image—all while maintaining a cost-effective packaging solution.

Customization Possibilities with UV Print on Metallic Cardboard

One of the greatest advantages of UV print on metallic cardboard is the endless design possibilities it offers. With UV printing, brands can experiment with various textures, finishes, and colors to create unique packaging that stands out. The ability to print fine details and intricate patterns with UV inks allows for a high level of customization, enabling brands to personalize their packaging and create limited editions.

Using metallic effects to enhance logo and branding elements can further elevate the packaging, making it more recognizable and memorable. This level of customization is particularly valuable for brands looking to create a strong visual identity and differentiate themselves in a crowded market.

UV Print on Metallic Cardboard for Different Industries

UV print on metallic cardboard is versatile and can be used across various industries to enhance packaging and attract consumers. In the beauty and cosmetics industry, stunning metallic packaging with UV print can convey luxury and quality, making products more desirable to consumers. UV-printed metallic packaging is also used in the food and beverage industry to ensure safety and appeal, as it provides a barrier against moisture and preserves the freshness of the product inside.

For electronics and gadgets, UV print on metallic cardboard offers durable packaging that protects delicate items while creating a sleek, modern appearance. The versatility of UV printing allows it to be tailored to the specific needs of different industries, making it a valuable tool for brands looking to enhance their packaging.

Challenges and Considerations in UV Printing on Metallic Cardboard

While UV printing on metallic cardboard offers many benefits, there are also challenges and considerations to keep in mind. Potential pitfalls include issues with ink adhesion, color consistency, and curing time, which can affect the quality of the print. To achieve the best results, it's important to prepare your artwork carefully, ensuring that it is optimized for UV printing and metallic surfaces.

Choosing the right metallic cardboard and UV printer is also crucial. Not all metallic cardboards are created equal, and selecting a high-quality material that is compatible with UV printing can make a significant difference in the final product. Additionally, working with an experienced UV printer who understands the nuances of printing on metallic surfaces can help you avoid common pitfalls and achieve the best results.

Steps to Get Started with UV Print on Metallic Cardboard

If you're considering UV print on metallic cardboard for your packaging, there are several steps you can take to get started. First, select the right printing partner who has experience with UV printing on metallic surfaces. Look for a printer who has a strong portfolio and can provide references or samples of their work. This will ensure that they have the expertise needed to deliver high-quality results for your project.

Before committing to a print run, ask key questions about the process. Inquire about the types of UV inks they use, their experience with metallic cardboard, and their quality control measures. It’s also important to discuss timelines, costs, and any potential challenges that could arise during production. Understanding these factors upfront can help you avoid surprises and ensure a smooth printing process.

To achieve the best results from your UV printing project, provide your printer with detailed artwork that is tailored for UV printing on metallic surfaces. Pay attention to color profiles, gradients, and any metallic effects you want to incorporate. Work closely with your designer and printer to ensure that the final product aligns with your vision and meets your branding and marketing goals.

Future Trends in UV Printing on Metallic Cardboard

The future of UV printing on metallic cardboard looks bright, with continuous innovations pushing the boundaries of what’s possible. One area of growth is in UV LED printing technology, which offers several advantages over traditional UV curing methods. UV LED printers are more energy-efficient, have a longer lifespan, and produce less heat, which reduces the risk of damage to sensitive materials like metallic cardboard.

Emerging trends in metallic packaging design are also shaping the future of UV printing. There is a growing demand for more intricate and visually engaging packaging, with designers experimenting with textures, holographic effects, and other eye-catching elements. These trends are driving the development of new UV inks and coatings that can create unique finishes and effects on metallic cardboard.

As the packaging industry continues to evolve, UV printing on metallic cardboard is expected to play an increasingly important role. With advancements in technology and materials, brands will have more opportunities to create standout packaging that not only looks good but also meets sustainability and cost-efficiency goals.

Case Studies: Success Stories with UV Print on Metallic Cardboard

To illustrate the benefits of UV print on metallic cardboard, let's look at some success stories from top brands that have leveraged this innovative technology to boost their packaging.

Case Study 1: A Beauty Brand’s Journey to Luxurious Packaging

A luxury beauty brand wanted to enhance its packaging to reflect the high quality of its products. By switching to UV print on metallic cardboard, they were able to create stunning, high-shine packaging that captured the essence of luxury and sophistication. The metallic finish, combined with vivid UV-printed graphics, helped the brand stand out on the shelf and increase its perceived value among consumers. This change not only boosted sales but also enhanced brand loyalty, as customers were impressed by the premium packaging and overall unboxing experience.

Case Study 2: A Beverage Company’s Success with Eye-Catching Designs

A beverage company sought to differentiate its product in a crowded market by using UV print on metallic cardboard for its packaging. By incorporating bold colors and metallic effects, they were able to create a unique and visually striking design that caught the attention of consumers. The durable UV print ensured that the packaging remained intact and vibrant, even in cold or wet conditions, making it perfect for beverages that are stored in refrigerators or coolers. This strategic use of UV printing not only enhanced the product's appeal but also reinforced the brand's image as innovative and forward-thinking.

Customer Perception and UV Print on Metallic Cardboard

Customer perception plays a critical role in the success of packaging, and UV print on metallic cardboard has been shown to positively influence how consumers view a brand. Shiny, metallic packaging with crisp UV prints often gives the impression of luxury and quality, making products more attractive to buyers. Consumers tend to associate such packaging with premium products, which can justify higher price points and increase overall sales.

The psychology behind luxury packaging and customer loyalty is fascinating. When customers perceive a product as high-end, they are more likely to feel a sense of pride and satisfaction in their purchase. This emotional connection can foster loyalty and encourage repeat purchases, as customers seek to replicate the positive experience they had with the initial product.

Real-life examples of positive customer feedback further highlight the impact of UV print on metallic cardboard. Many consumers report feeling more satisfied with their purchase when it comes in visually appealing, high-quality packaging. They often share their experiences on social media, creating organic marketing opportunities for the brand and helping to attract new customers.

Integrating UV Print into Your Packaging Strategy

If you’re considering integrating UV print on metallic cardboard into your packaging strategy, it’s important to assess whether this method is right for your brand. Consider the specific needs of your products, your target audience, and your brand’s image. If you want to convey luxury, quality, and innovation, UV printing on metallic cardboard could be a perfect fit.

Once you’ve decided to proceed, take steps to incorporate UV printing into your existing packaging strategy. Start by collaborating with designers to create artwork that leverages the unique benefits of UV printing, such as vibrant colors and metallic effects. Work closely with your printing partner to ensure that the final product meets your expectations and aligns with your brand's identity.

Collaboration is key when integrating UV print into your packaging strategy. By working with experienced designers and printers, you can achieve a seamless transition and create packaging that resonates with your audience and enhances your brand.

Common Misconceptions About UV Print on Metallic Cardboard

There are several misconceptions about UV print on metallic cardboard that can deter brands from exploring this innovative packaging option. One common myth is that UV printing on metallic cardboard is prohibitively expensive. While it’s true that the initial costs may be higher than traditional printing methods, the long-term benefits—such as durability, reduced waste, and enhanced brand perception—often outweigh these upfront expenses.

Another misconception is that UV-printed metallic cardboard isn’t sustainable. In reality, UV printing can be more eco-friendly than other methods due to its lower waste output and reduced emissions. Additionally, many metallic cardboards are recyclable, and advancements in UV ink formulations continue to improve their environmental impact.

It’s also important to clarify the differences between UV and other printing methods. Unlike traditional printing, which often requires additional coatings or treatments to achieve similar effects, UV printing can produce high-quality results in a single pass. This efficiency makes UV printing a valuable option for brands looking to enhance their packaging without compromising on quality or sustainability.

Expert Tips for Maximizing the Benefits of UV Print on Metallic Cardboard

To maximize the benefits of UV print on metallic cardboard, there are several expert tips to keep in mind.

-

Focus on achieving vibrant colors and sharp details by using high-quality UV inks and properly preparing your artwork. Pay attention to color profiles and ensure that your design takes full advantage of the reflective qualities of metallic cardboard.

-

Maintaining quality and consistency across print runs is also crucial. Work with a reputable printer who has experience with UV printing on metallic surfaces and can provide quality control measures to ensure that every print meets your standards.

-

Finally, consider leveraging UV print for seasonal promotions and special editions. The versatility of UV printing allows you to create unique, limited-edition packaging that can drive sales and create excitement around your brand. By using UV print strategically, you can enhance your packaging and make a lasting impression on consumers.

Conclusion

UV print on metallic cardboard offers a powerful combination of aesthetic appeal, durability, sustainability, and cost-efficiency, making it an excellent choice for brands looking to elevate their packaging. By understanding the unique benefits of this innovative printing method and how it can enhance your products, you can create packaging that not only looks good but also drives sales and builds customer loyalty.

Whether you’re in the beauty, food and beverage, or electronics industry, UV print on metallic cardboard can provide the perfect solution for your packaging needs. Explore the possibilities and consider incorporating UV printing into your strategy to stay ahead of the competition and meet the evolving demands of today’s consumers. The future of packaging is bright, and UV print on metallic cardboard is poised to play a significant role in shaping it.