Table of Contents

In today’s competitive market, getting cereal packaging right is crucial for brand appeal, shelf impact, and customer satisfaction. Measuring cereal box dimensions accurately is the first step in good packaging design. This design attracts consumers and helps control production and shipping costs. Whether it’s a regular cereal box size or a special custom design, knowing how to measure is important. Using the right dimensions can greatly improve packaging success.

Understanding the basic measurements of cereal boxes can help you design packaging that fits store requirements. This packaging can also attract customers. This guide will walk you through the best methods to measure, plan, and design cereal box packaging that is both functional and appealing.

Tools Needed for Measuring Cereal Box Dimensions

To get started, you’ll need just a few simple tools to take accurate measurements:

-

Measuring Tape: A flexible measuring tape is best for measuring height, width, and depth precisely. The tape should be long enough to handle larger family-size cereal boxes if needed.

-

Notebook or Digital Tool: Recording measurements accurately ensures there’s no confusion when moving to the design phase. A digital tool can be helpful if you’re calculating volumes or comparing different box sizes.

When measuring, it’s crucial to be precise, as even a small error can impact everything from box design to shelf placement. Aim to measure each dimension twice to confirm accuracy, which will save time and prevent mistakes in packaging production.

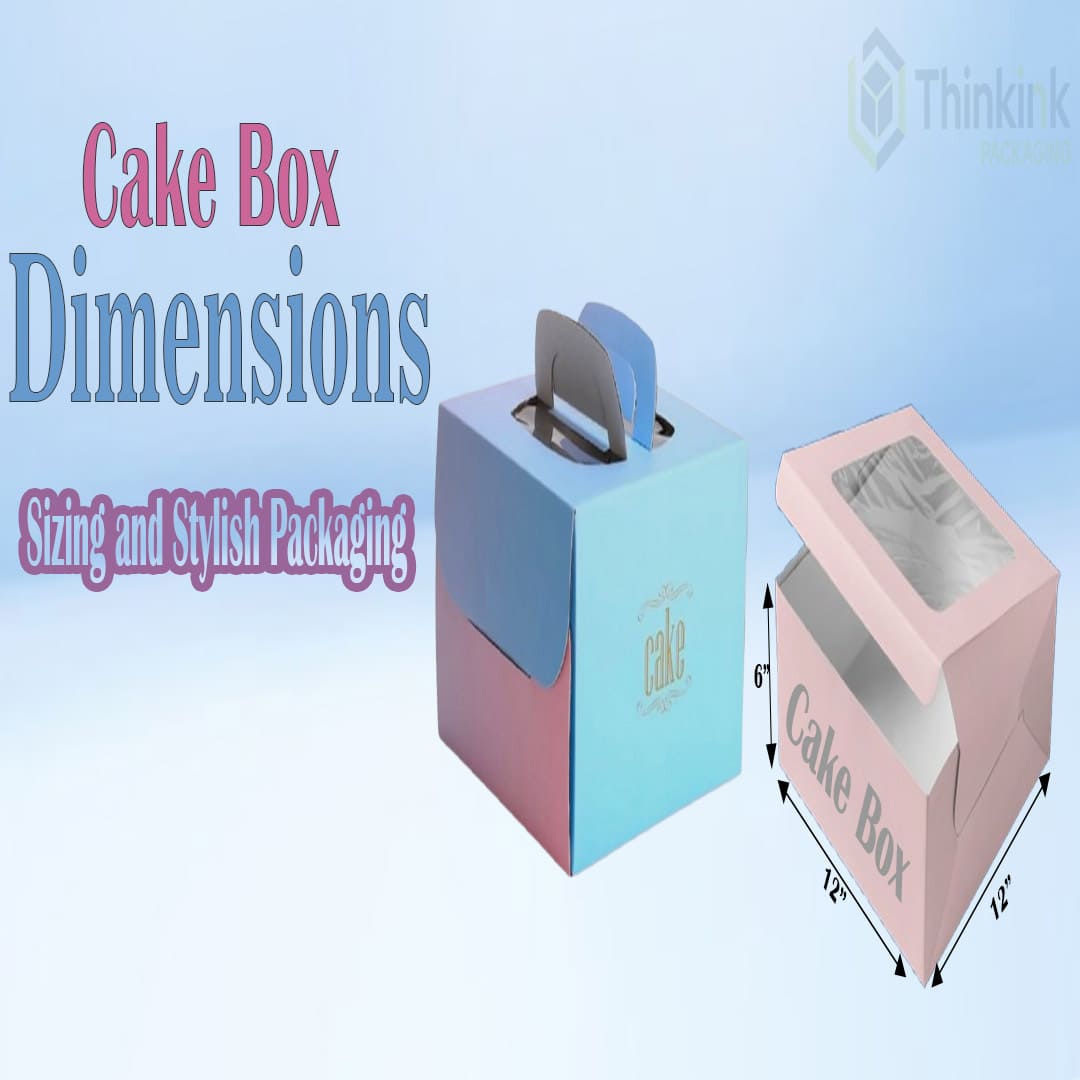

Key Dimensions to Measure

Accurate measurements focus on three main dimensions: height, width, and depth. These dimensions are important for making a good fit. They also help assess the cereal box's shelf space and design.

-

Box Height: Measure from the base to the top of the box. Height is important when designing custom packaging or family-size boxes. It affects both storage and how well products are seen on shelves.

-

Box Width: The width, measured from side to side, determines how much shelf space the box will occupy. Accurate width measurements are essential for organizing multiple boxes on a shelf or in storage.

-

Box Depth: Depth, or thickness, is measured from the front to the back of the box. This measurement impacts the box’s stability on the shelf and affects how well it stacks during transport.

Measuring each part carefully helps create a balanced design. This ensures the cereal box meets storage needs, looks good, and holds enough product for customers.

The table below shows standard dimensions for each type of cereal box:

| Creal box types | Lenght | Width | Hight |

|---|---|---|---|

| Regular/ Standard | 6-8 Inch | 2-3 Inch | 8-12 Inch |

| Multi-Packed | Different | Vary | Different |

| Family-Sized | 8-10 Inch | 2-3 Inch | 10-15 Inch |

Importance of Custom Packaging in Cereal Box Design

Custom packaging plays a big role in setting your product apart. Accurate measurements make it easier to create your own eye catching cereal box with branded elements that not only look good on the shelf but also fit well with standard storage and shipping needs. With custom packaging, you have the freedom to experiment with different dimensions while keeping everything within production guidelines.

When choosing the best custom packaging for your cereals, focus on measurements that balance design and practical storage. You can explore options for custom designs that capture attention, improve customer experience, and maintain cost-effectiveness.

Designing for Shelf Appeal and Storage

An effective cereal box design doesn’t just look good; it’s functional. Accurate dimensions are important for making packaging that meets retail needs. They also help attract customers' attention on the shelf.

-

Shelf Space Optimization: Ensuring that your cereal box fits well with other items on the shelf maximizes retail space. This keeps products organized and gives your brand a polished, professional look.

-

Eye-Level Appeal: Height is an important factor when thinking about shelf placement. Positioning your cereal box to match a consumer’s natural line of sight helps it stand out and boosts sales.

-

Efficient Storage: Retailers appreciate packaging that fits easily in stock rooms or on store shelves. Accurately measured boxes can be packed and stored without extra hassle, improving stock rotation and saving time.

To learn more about creating great designs, check out this guide on packaging design. It offers tips for grabbing consumer attention and making a strong impact on shelves.

Benefits of Accurate Dimensions for Shipping and Cost-Effectiveness

Precise measurements play a big role in the shipping and transportation of cereal boxes. Incorrectly sized boxes may lead to wasted space, which drives up shipping costs. When you size boxes correctly, you can fit more units in each shipment, making transportation more cost-effective.

-

Reducing Wasted Space: Boxes with well-thought-out dimensions minimize the risk of empty space. Efficient box sizing allows more boxes to load per truck, which lowers transportation costs and improves efficiency.

-

Packaging Materials Efficiency: Proper dimensions ensure the right amount of packaging material is used, reducing waste and contributing to a more eco-friendly approach. This also helps cut down on packaging expenses and allows for more sustainable practices.

-

Storage Considerations: Accurate measurements help products fit seamlessly into warehousing systems, allowing for better organization and reducing the chance of damage.

Incorporating measurements that optimize storage and shipping can lead to significant cost savings over time. Look for ideas on how a well-designed cereal box can enhance brand image and function. Consider various custom packaging options. These options can provide both style and efficiency.

Customer Impact and Brand Loyalty

Customers appreciate packaging that feels made for them, both in terms of look and usability. A cereal box that is easy to hold, looks good, and is strong can help build customer loyalty and a positive brand image.

-

Consumer Engagement: Packaging design can draw customers in, making them more likely to choose your product. Well-sized and attractive boxes capture attention, while poor packaging design can turn customers away.

-

Enhanced Experience: Packaging that’s easy to open and pour from enhances the customer’s experience. Precise measurements ensure the box holds enough product to satisfy while still being manageable.

-

Brand Trust and Loyalty: Consistency in packaging design helps customers recognize and trust your brand. Boxes that stay the same shape and size contribute to a cohesive brand image, increasing loyalty over time.

The right packaging can boost customer engagement and build brand loyalty. This helps achieve long-term success in a competitive market.

Read More: Key to Success with Custom Cereal Boxes – Your Guide to Making the Right Packaging Choice

Conclusion

Learning how to measure cereal box dimensions has many benefits. It can save money in production and shipping. It also improves shelf appeal and customer satisfaction. By focusing on precise measurements and custom packaging, you can create packaging solutions that stand out in stores. This will help keep customers coming back.

If you want to improve your cereal packaging, check out our guide to comparing cereal packaging options and finding the best design for your brand. See how great design can boost your brand in stores.