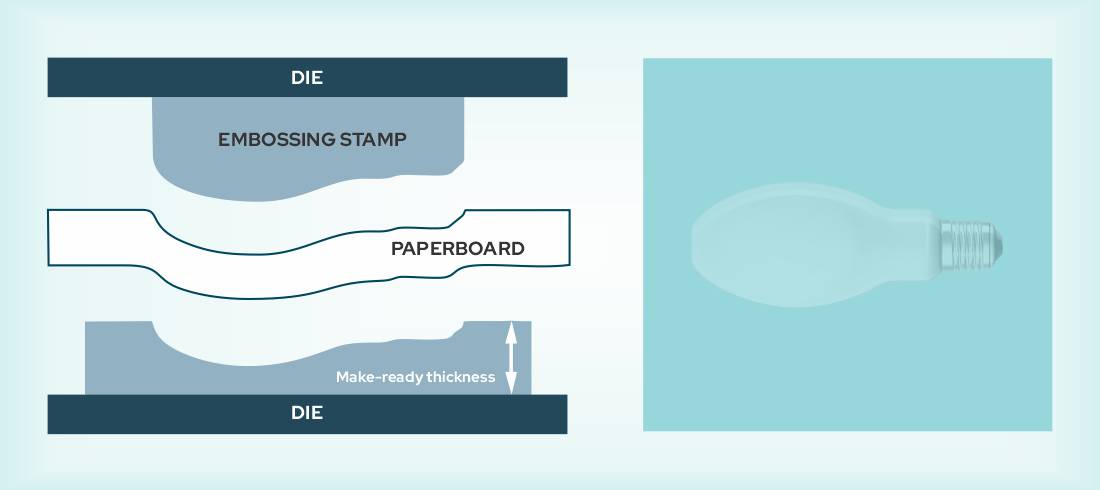

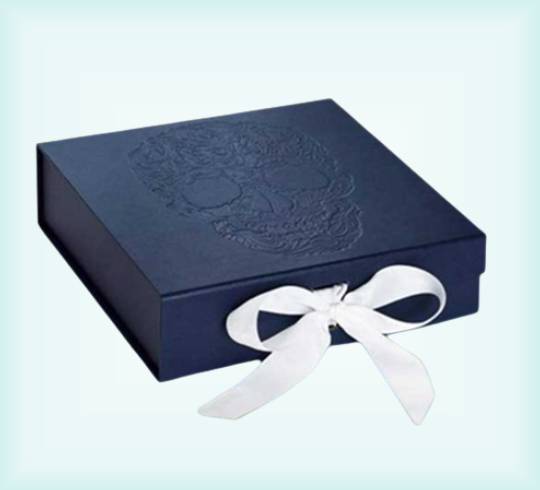

Debossing

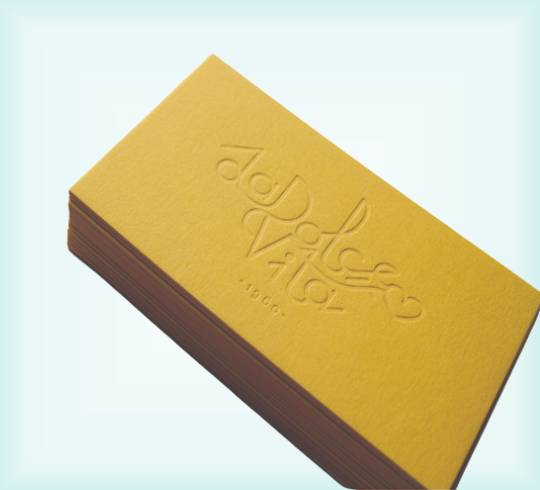

The process of debossing involves pressing a design onto a paperboard using a heated die. This creates engraved areas on the surface of the material, giving the impression of a debossed pattern. It’s often used to create decorative patterns on the packaging.

-

Create eye-catching designs

-

Engraved Touch

-

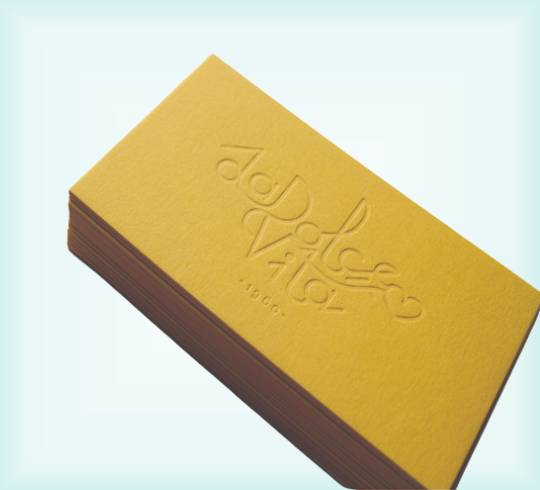

Ideal for logo, company name, and text

-

Increase brand awareness

We offer a range of materials and special finishes which you can use to create custom boxes that suit your brand. From the hardwearing corrugated cardboard, to the rustic kraft paper or cardstock as an alternative, we have options for each product you make. For an elegant touch, we have various special finishes including matte or glossy lamination, embossing or debossing for additional textures and foil stamping for luxurious look while spot UV coating will emphasize on some specific elements. With die-cutting facilities in place, one has even greater freedom of creating unique presentations through making custom shapes and windows. Our customized packaging options will take your brand to the next level and ensure it remains unforgettable.

The debossing process involves using a special tool to press down on the material's surface without actually touching the ink. Add that extra touch with Debossing. The subtle shadows and highlighted text will stand out while the debossing process gives your package a clean, professional feel. You'll be able to make your logo or key messages more eye-catching with debossed effect. From corrugated and folding cartons to luxury rigid packaging, Debossing is the way to go!

Debossing Process