Hot Foil Stamping

The process involves heating a sheet of aluminum foil to around 200 degrees Celsius, applying the design onto the foil using a heated die, and then cooling down the foil before peeling off the finished product. Thus this hot foil stamping method allows designers to create intricate details on products without having to use expensive printing techniques. So it’s a quick and simple method of creating high-quality, eye-catching effects on printed boxes.

- Also great for Branding

- Adds a premium finishing touch

- Can be applied to almost any cardboard surface

- Will certainly, create a new look

- Also available in various colors

Best Used With

- Overview

- Available Options

Hot foil stamping is a process where a thin layer of metal is applied to a substrate using heat and pressure. The result is a shiny, durable surface that can be printed on. It’s often used for branding purposes, but can also be used to create customized packaging. This process is often used on luxury boxes but can also be applied to boxes for clothing, cosmetics accessories, home goods, and even food packaging.

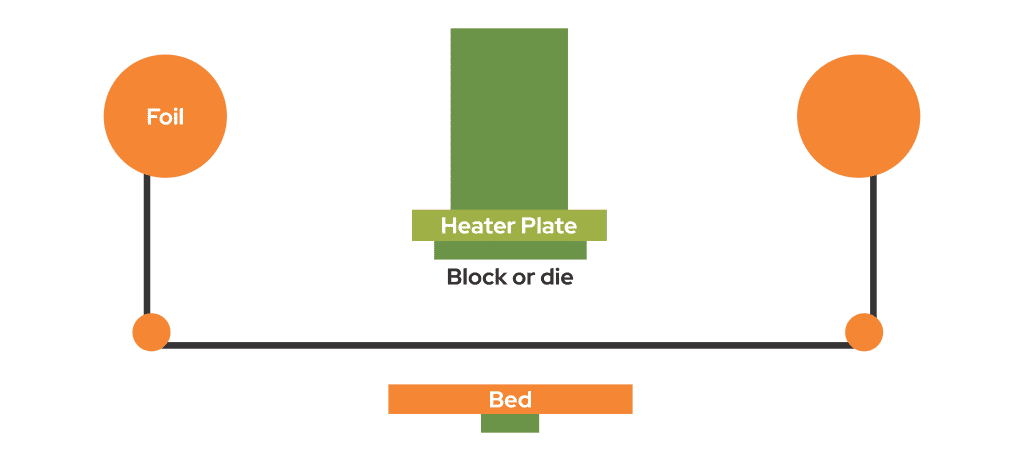

Foil Stamping Process

Foil Stamping Process

Metallic Foil

Metallic foils are coated with a thin layer of aluminum. The aluminum layer acts like a mirror, reflecting light back through the package. This makes the contents appear brighter than if there were no reflective surfaces.

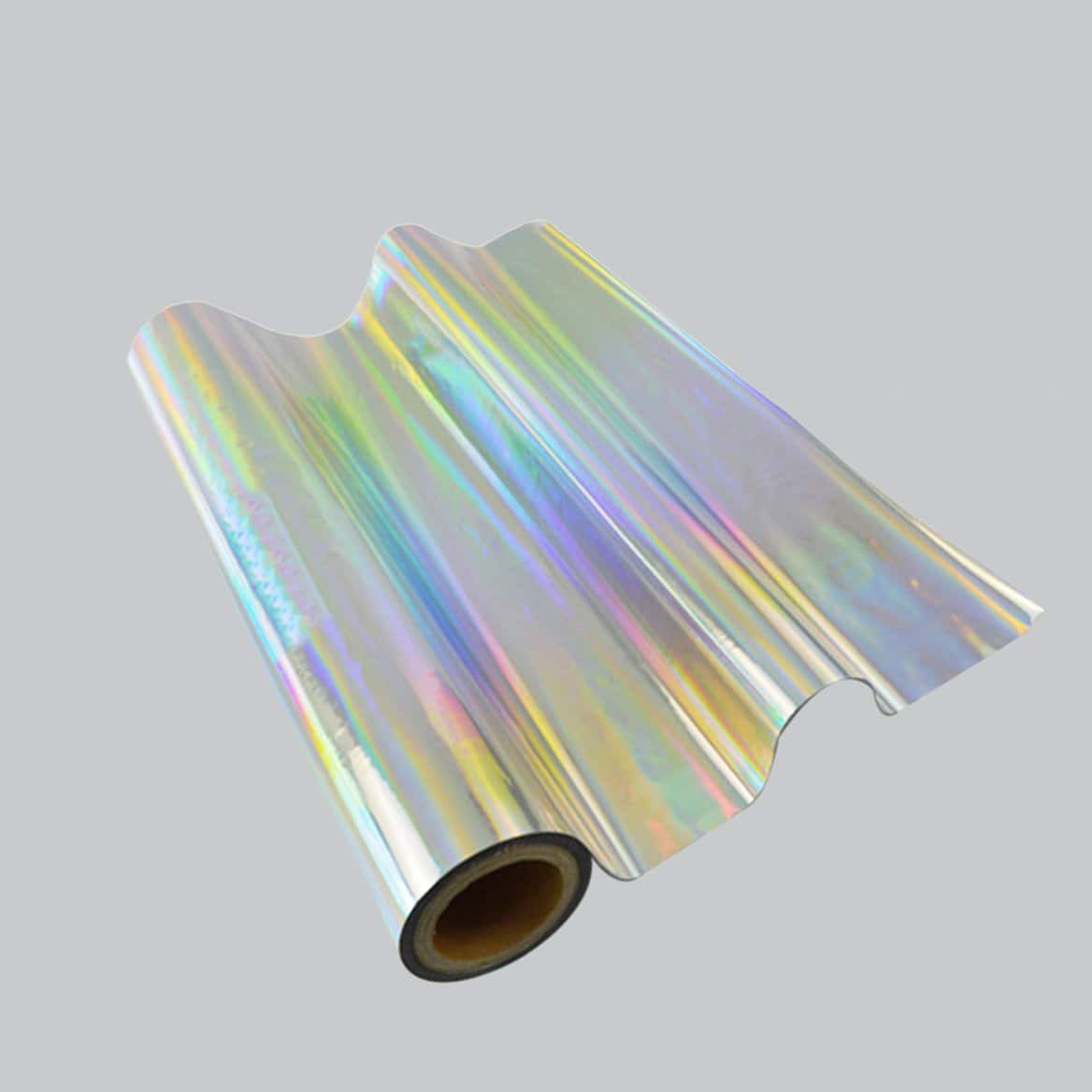

Holographic Foil

Holographic coloration is a type of optical illusion where foil appears to change color when viewed from different angles. The phenomenon occurs because light reflects off the surface of an object differently depending on how it hits the surface. This causes the box to appear to change colors.