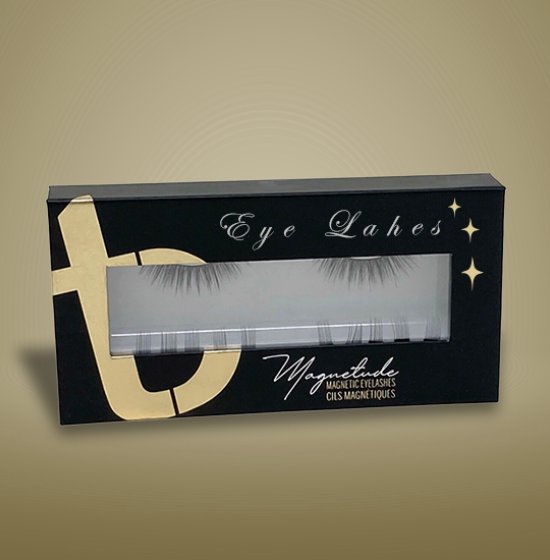

Hot Foil Stamping

The process involves heating a sheet of aluminum foil to around 200 degrees Celsius, applying the design onto the foil using a heated die, and then cooling down the foil before peeling off the finished product. Thus this hot foil stamping method allows designers to create intricate details on products without having to use expensive printing techniques. So it’s a quick and simple method of creating high-quality, eye-catching effects on printed boxes.

-

Also great for Branding

-

Adds a premium finishing touch

-

Can be applied to almost any cardboard surface

-

Will certainly, create a new look

-

Also available in various colors

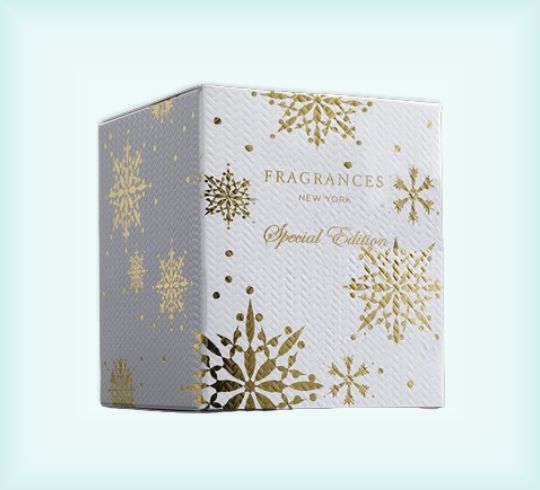

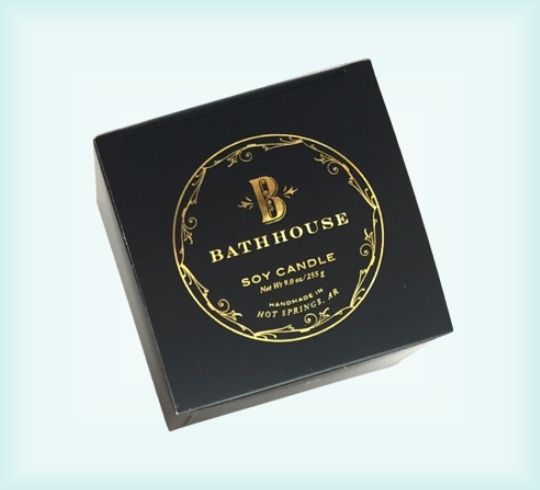

We offer a range of materials and special finishes which you can use to create custom boxes that suit your brand. From the hardwearing corrugated cardboard, to the rustic kraft paper or cardstock as an alternative, we have options for each product you make. For an elegant touch, we have various special finishes including matte or glossy lamination, embossing or debossing for additional textures and foil stamping for luxurious look while spot UV coating will emphasize on some specific elements. With die-cutting facilities in place, one has even greater freedom of creating unique presentations through making custom shapes and windows. Our customized packaging options will take your brand to the next level and ensure it remains unforgettable.

Hot foil stamping is a process where a thin layer of metal is applied to a substrate using heat and pressure. The result is a shiny, durable surface that can be printed on. It’s often used for branding purposes, but can also be used to create customized packaging. This process is often used on luxury boxes but can also be applied to boxes for clothing, cosmetics accessories, home goods, and even food packaging.

Foil Stamping Process

Foil Stamping Process

A hot stamping color chart illustrates a cross section of metallic and pigment foiling that can be used in hot foiling and showcases every color with finish such as gloss, matte, holograph and satin. This chart help in choosing the right color for the creation of the nice looking printed items and packaging.

Hot Foiling Colors Chart