Breathe New Life to your Packaging with Custom Effects at No Extra Cost

Quality

Sustainable

3D Design Support

Free Shipping

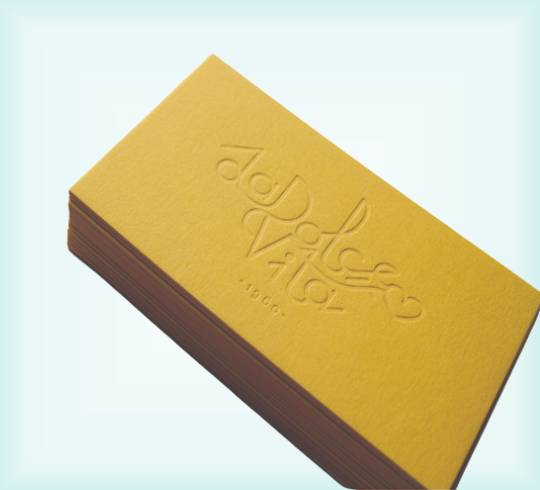

Special Effects

This relates to designing the packaging and incorporating particular features and materiel on to the packaging to make the product to be unique and easily noticeable amidst the rest on the shelves. Some of such outcomes include foil or metallic efficiencies, Raised or Indentations, spot UV varnish, textured surfaces, and functions such as Quick Response code. These techniques not only grab the attention of the target customer but also give them a perception of quality and something new which makes the product stand out among similarly categorized products.

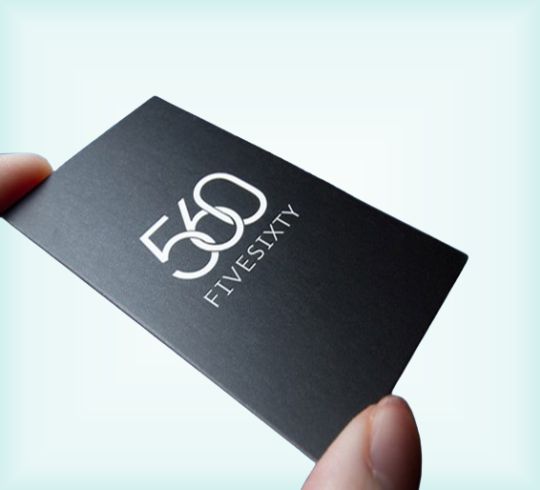

Coating

Decorative aspect of the covering includes the application of a thin layer on the outer surface of the box with the aim of beautifying the surface, protection and functionality. Some of the typical coatings are gloss, matte, and soft touch which different in terms of luster and texture. Coatings could help resist moisture and fingerprints, as well as abrasion, and make the packs feel and look better for consumers, enhancing print quality.

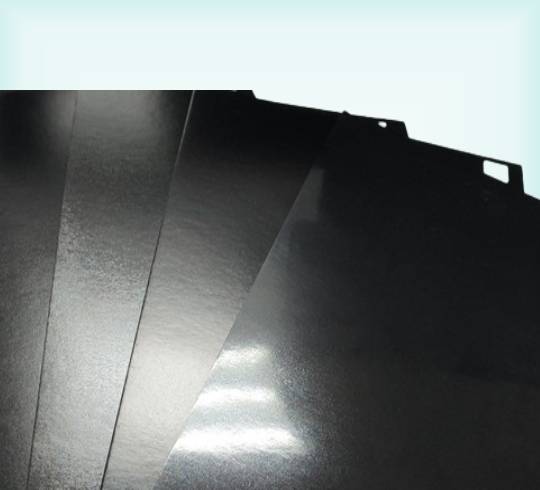

Lamination

Lamination of the packaging is the process where a plastic film is applied to the surface of the packaging material as a paper or cardboard. This process contributes to increased protection against physical dangers and various climatic conditions, as well as increased water resistance and tear strength of the respective packaging materials. It can also enhance the appearance by providing different lamination that is gloss, matte, and soft touch which makes the colors to be more appealing and the designs beautiful.

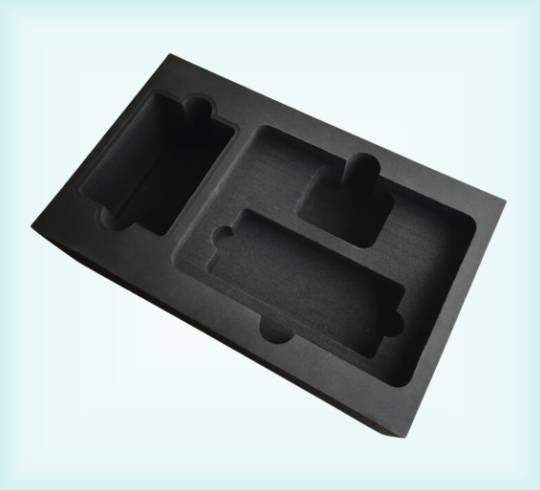

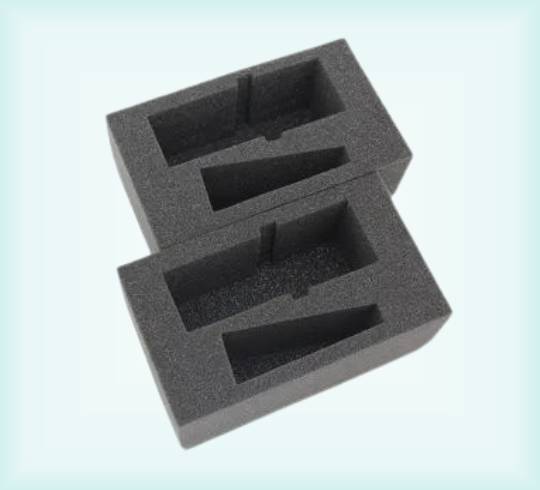

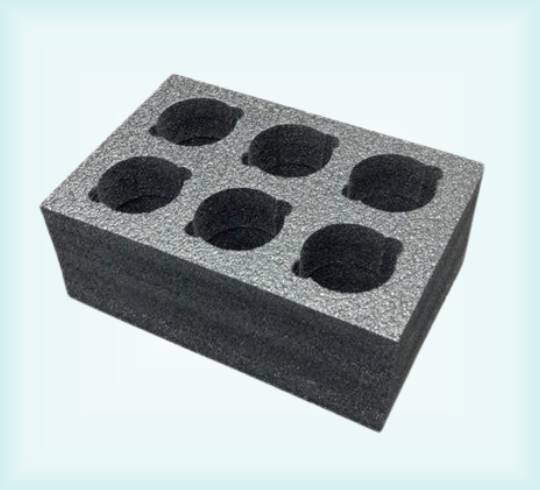

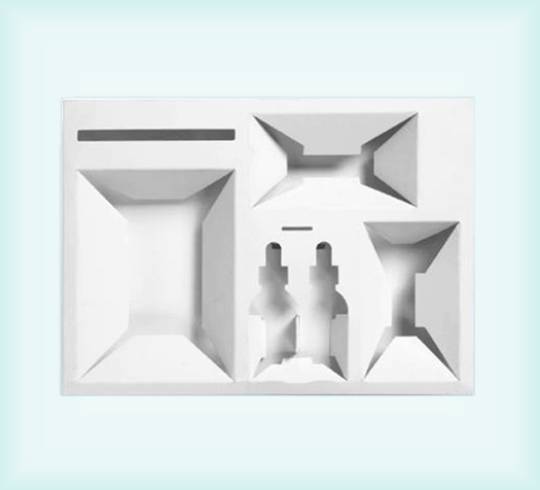

Custom Inserts

In packaging, custom inserts are special items which are applied inside a box to ensure that products contained in the box are well protected during handling and shipment. These inserts may be created with materials such as foam, cardboard, plastic or molded pulp and as such are intended to conform to the shape of the items to be packaged. They improve the unboxing process, order the ingredients of one set more conveniently, protect items from scratches and help to provide more comfortable places for products themselves.

Not Sure

Which Material Or Option To Choose

You’ll find answers below to some common questions about creating your customized boxes, various customer has different needs, so dont hesitate to reach us with any order, and find your one-stop packaging solution at Thinkink Packaging.