Reverse Tuck End

Get an Instant Quote

- Custom Sizes & Styles

- Low Minimum to Start

- Fast Turnaround

- Free Shipping

- No Hidden Charges

- Free Design Support

- Competitive Prices

- High Quality Printing

Quality

Sustainable

3D Design Support

Free Shipping

Detailed Product Overview and Analysis

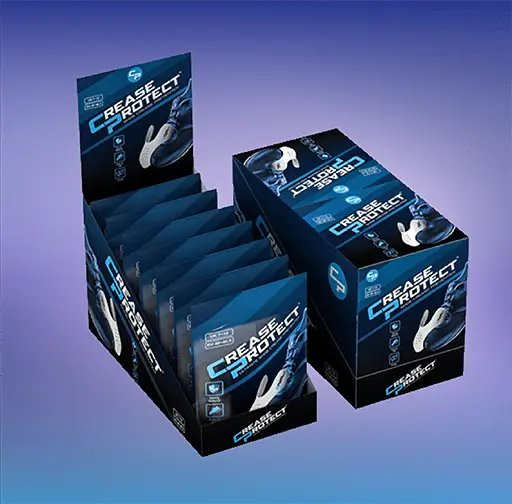

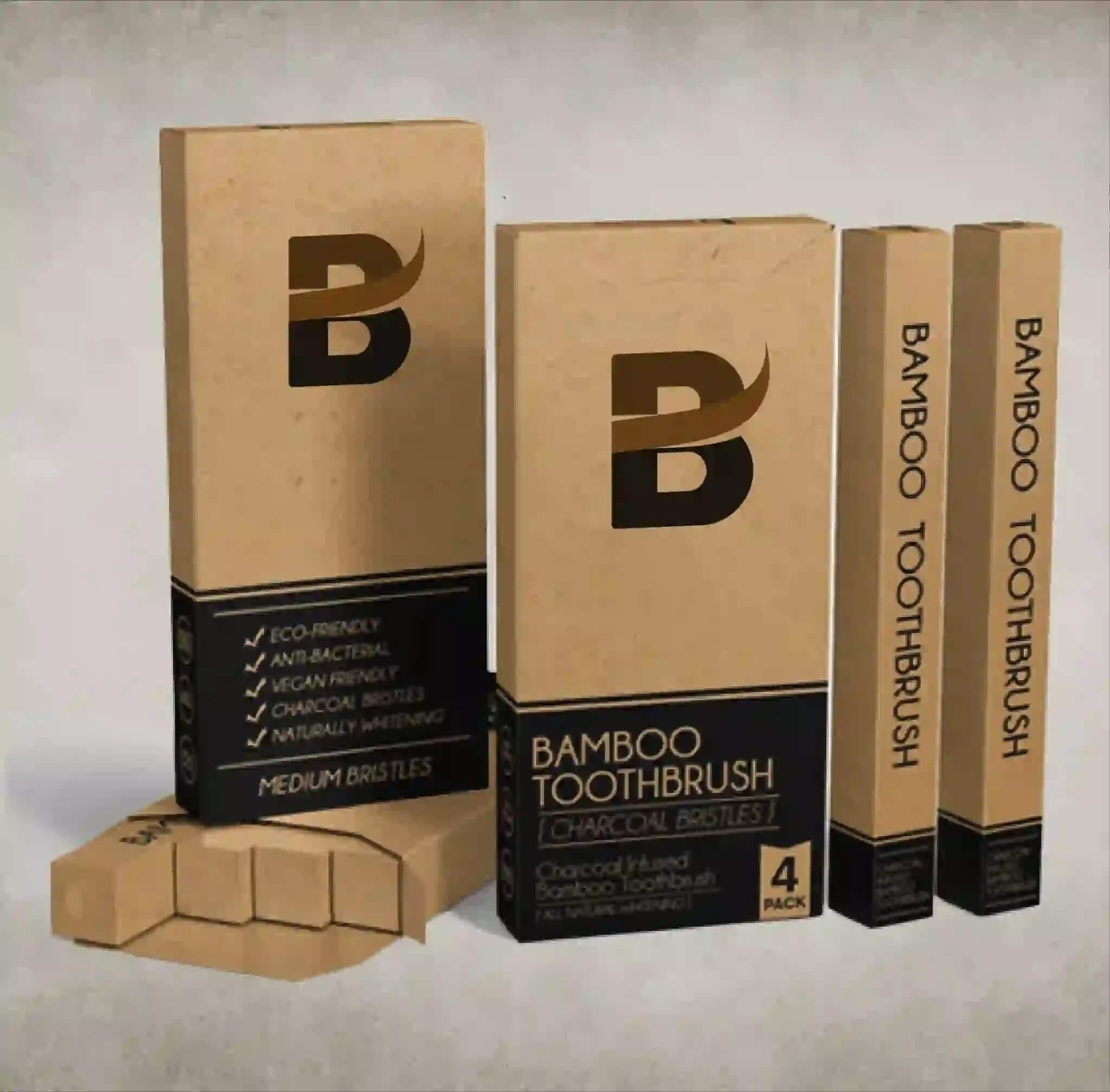

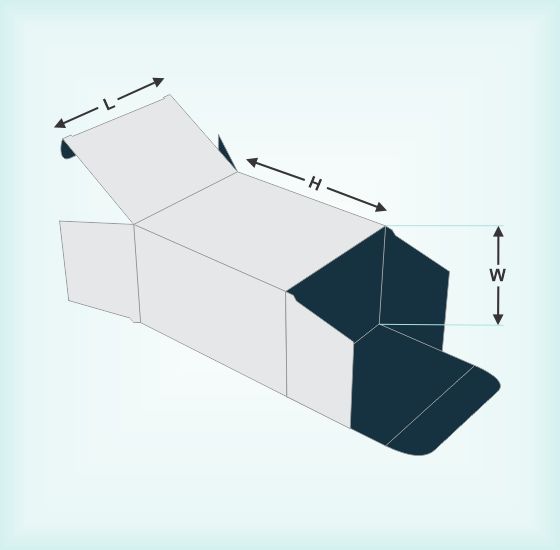

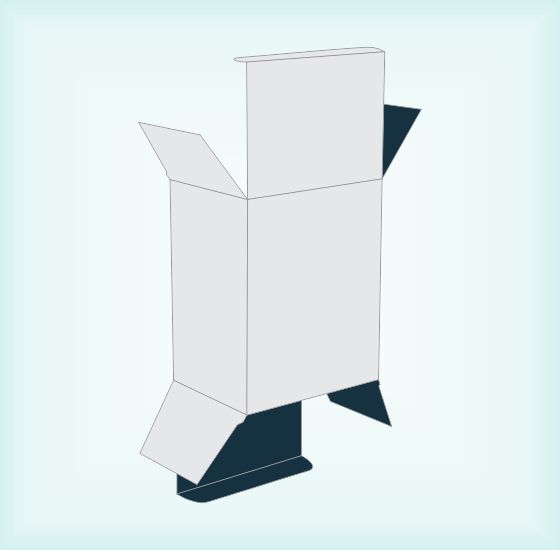

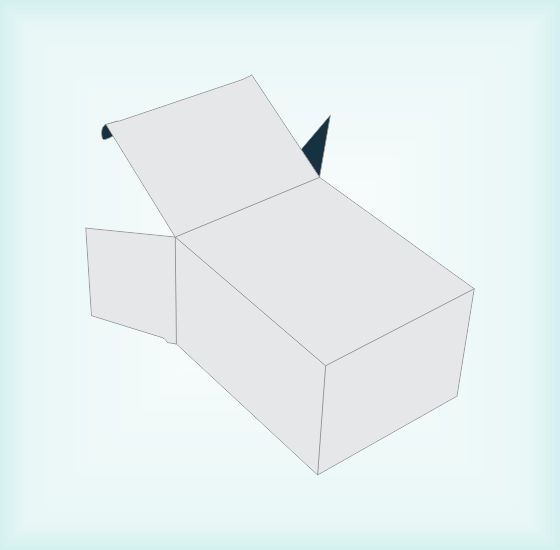

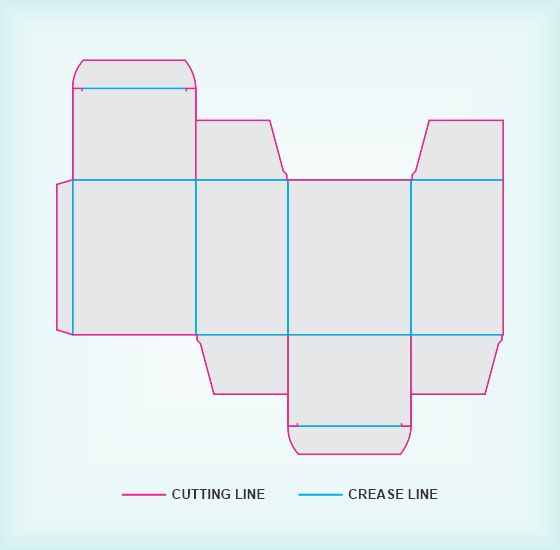

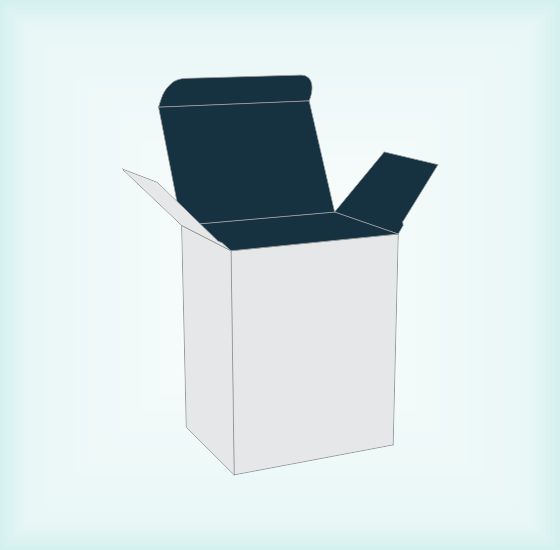

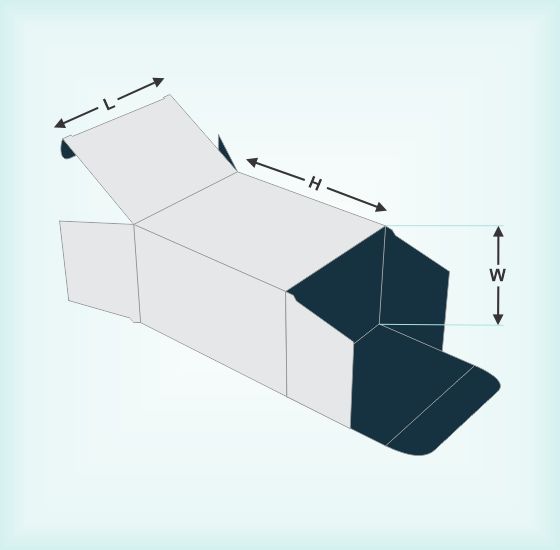

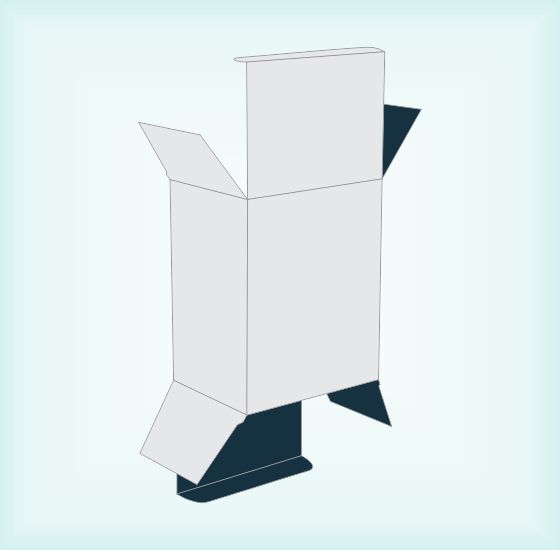

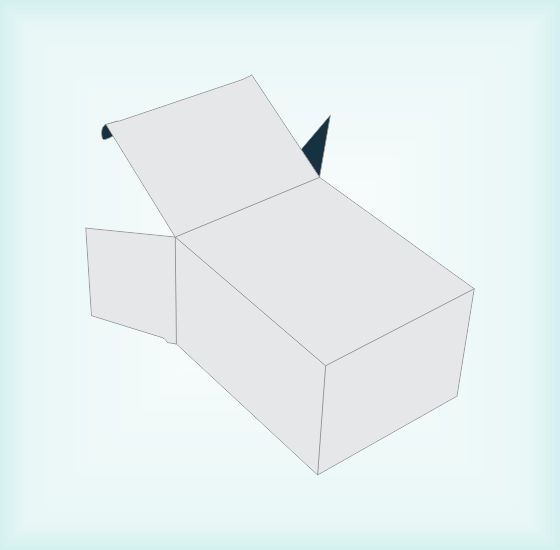

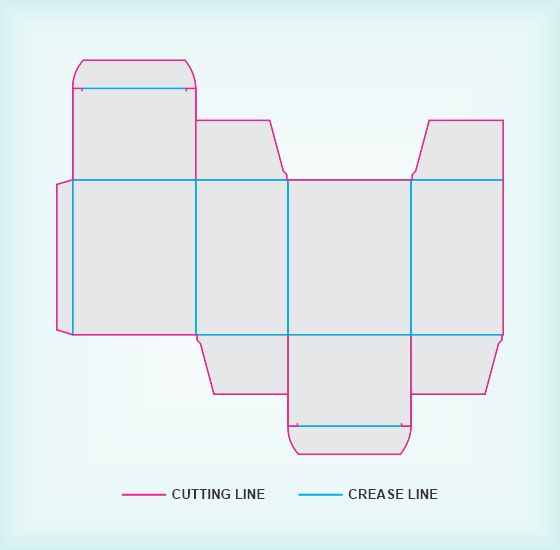

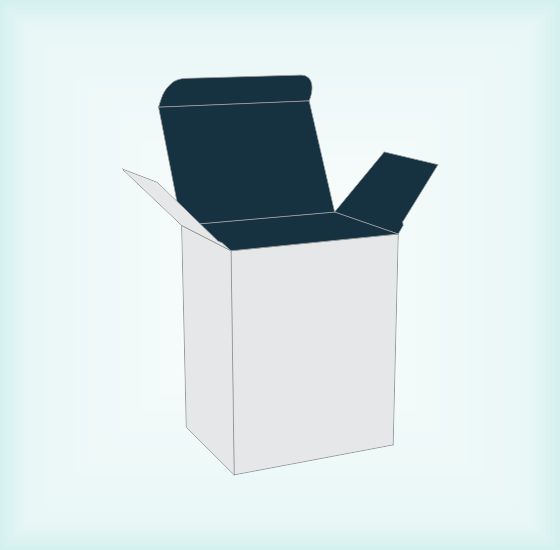

Reverse Tuck End Boxes are used in many industries like Pharmaceuticals, Households, Electronics, Cosmetics etc. They are made up of two parts, main body and tuck flaps. Main body consists of four panels and a glued flap. These panels are connected using adhesive tape or glue. The tuck flaps are attached from the top and bottom to the main body. It is designed so that when close this box tuck flap is locked with the dust flaps, opening and closing these boxes are so easy.

Reverse Tuck boxes are the best-selling product from Thinkink Packaging that offers a simple solution for those who want to print on their custom tuck ends. These boxes are recyclable and are available in a variety of sizes. They come pre-assembled and ready to use.

Everything You Need For The Perfect Packaging.

Thinkink Packaging has provided custom packaging solutions to a wide range of businesses worldwide. Built on experience working with a wide range of industries, we have curated a library of material options based on their capabilities for your conveniencebelow.

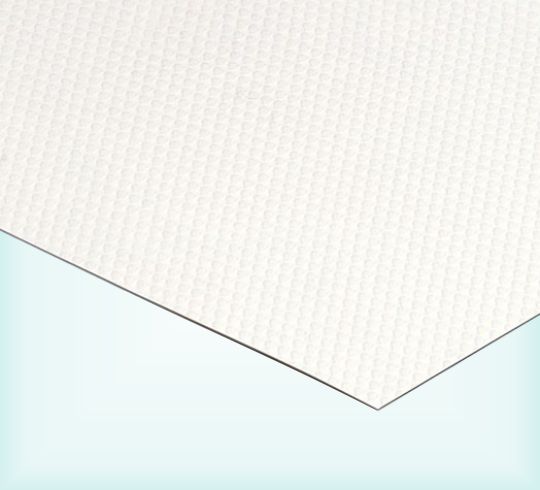

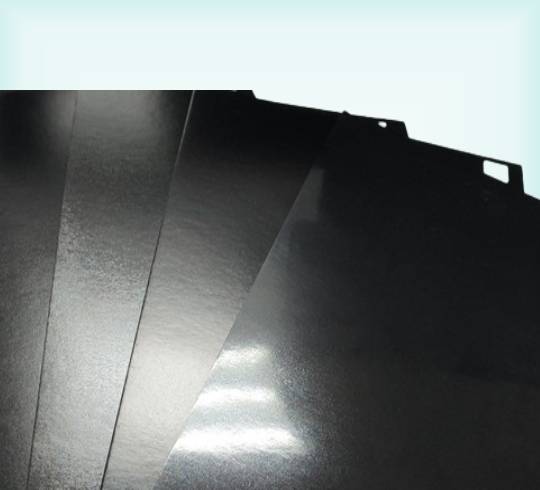

Discover our range of high-quality packaging materials designed to tailor your packaging order to perfection. From sturdy cardboard boxes to eco-friendly options, we have the ideal materials for your unique needs. Elevate your brand and protect your products with our customizable packaging solutions

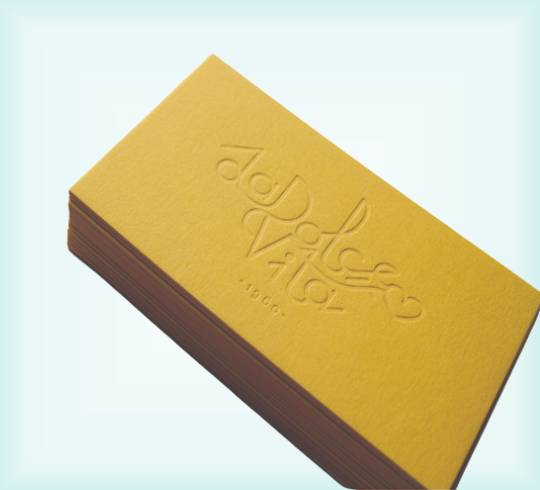

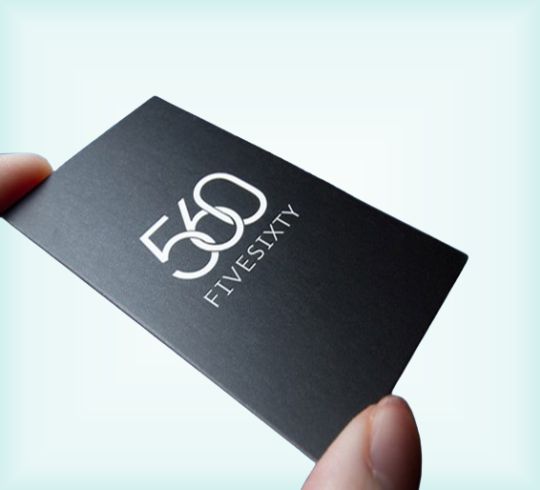

This relates to designing the packaging and incorporating particular features and materiel on to the packaging to make the product to be unique and easily noticeable amidst the rest on the shelves. Some of such outcomes include foil or metallic efficiencies, Raised or Indentations, spot UV varnish, textured surfaces, and functions such as Quick Response code. These techniques not only grab the attention of the target customer but also give them a perception of quality and something new which makes the product stand out among similarly categorized products.

Decorative aspect of the covering includes the application of a thin layer on the outer surface of the box with the aim of beautifying the surface, protection and functionality. Some of the typical coatings are gloss, matte, and soft touch which different in terms of luster and texture. Coatings could help resist moisture and fingerprints, as well as abrasion, and make the packs feel and look better for consumers, enhancing print quality.

Lamination of the packaging is the process where a plastic film is applied to the surface of the packaging material as a paper or cardboard. This process contributes to increased protection against physical dangers and various climatic conditions, as well as increased water resistance and tear strength of the respective packaging materials. It can also enhance the appearance by providing different lamination that is gloss, matte, and soft touch which makes the colors to be more appealing and the designs beautiful.

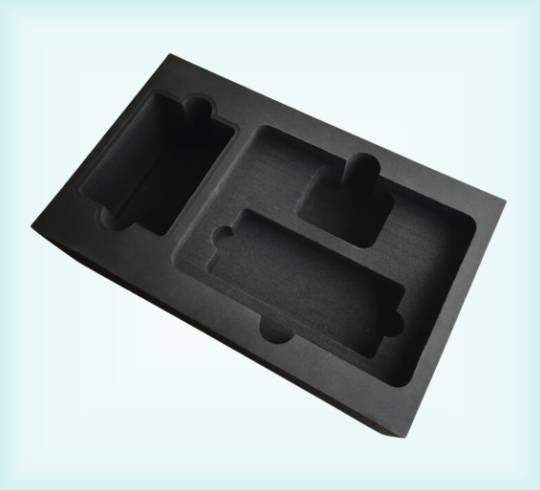

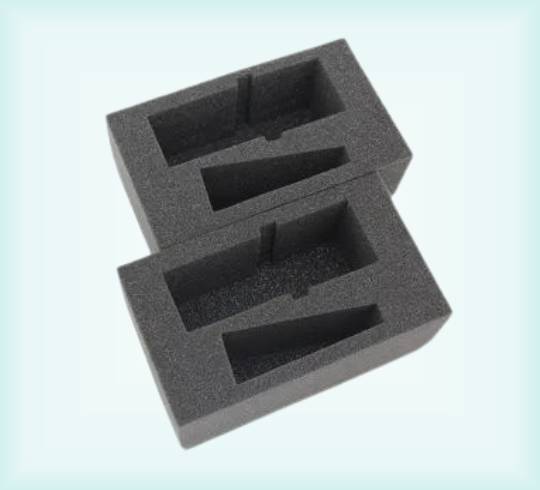

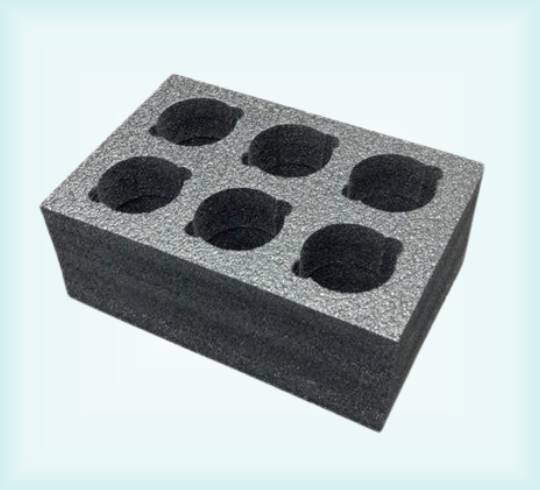

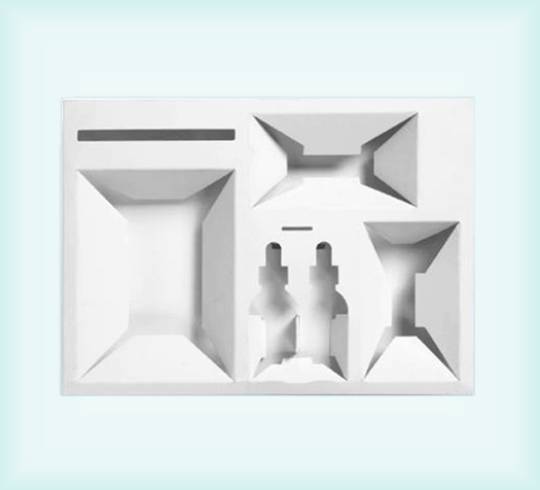

In packaging, custom inserts are special items which are applied inside a box to ensure that products contained in the box are well protected during handling and shipment. These inserts may be created with materials such as foam, cardboard, plastic or molded pulp and as such are intended to conform to the shape of the items to be packaged. They improve the unboxing process, order the ingredients of one set more conveniently, protect items from scratches and help to provide more comfortable places for products themselves.

Why Us?

Accelerating Innovations In

Custom Packaging

Over the course of many years, Thinkink Packaging have produced some of the finest product packaging marking a classy first impression and premium feel. We carry a wide expertise in producing packaging material for a range of products while making an innovative approach to cut down on costs. Primarily, our packaging is focused on three main aspects

Best Quality Of Packaging

We ensure that the quality is never at compromise.

Creative Packaging

Our packaging is creative for a unique-design approach.

Environmentally Friendly

We strictly follow sustainability protocols for packaging.

Our Ordering Process

Need custom packaging? Simplify the task with our four easy steps, and you'll quickly be on your way to fulfilling all your packaging requirements!

Personalize your packaging

Explore our extensive range of packaging solutions and customize them with our diverse options to create your ideal packaging.

Add to Quote and Submit

Once you've customized your packaging, just add it to your quote and submit your quotation for review by one of our packaging specialists.

Consult with Our Expert

Receive expert advice on your quotation to save costs, streamline efficiency, and reduce environmental impacts.

Production & Shipping

When everything is ready, let us handle your entire production and shipping process. Just sit back and wait for your order!

Request a free Sample Kit for Bulk Orders and Get 30% off

Receive a Complimentary Consultation and Request Your Sample Kit to Enhance Your Confidence in Selecting Thinkink Packaging as Your Product Packaging Partner.

Frequently Asked Questions

Not sure yet? That's okay, we've got you covered. Here are answers to common questions about creating a custom box design. Keep in mind that each order is unique, so feel free to contact us with any other questions you may have. We're here to help!

Reverse Tuck End (RTE) boxes are a type of packaging where the top flap tucks in one direction and the bottom flap tucks in the opposite direction.

Yes, we provide eco-friendly or sustainable packaging options for Reverse Tuck End.

Yes, we offer free samples to help you assess quality and design of our Reverse Tuck End before making a decision.

Indeed, it is protected to pay online because ThinkInk Packaging works just with the world’s most solid installment doors that incorporate PayPal, American Express, Visa, MasterCard, and Discover.

Typically you can expect your custom boxes to be ready for shipping within 10 to 15 business days from final approval of design.