UV Coating

UV coating is a type of coating used on the printed sheet to protect against damage caused by sunlight, moisture, heat, and scratches. It is applied to surfaces using a special process that involves exposing the cardboard sheet to high-energy rays. The rays penetrate the material and cause chemical reactions that bond molecules together. This creates a protective layer that prevents the underlying printed design from being damaged and gives shine.

-

Durable, long-lasting finish

-

Fast drying

-

Can be applied over existing print

-

Protects against scratches, stains, and fading

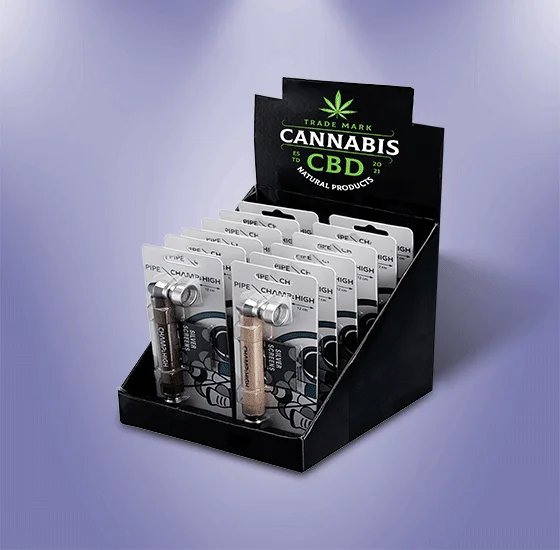

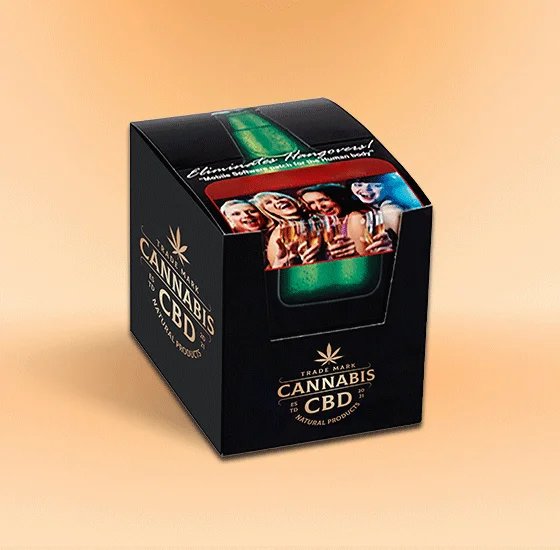

We offer a range of materials and special finishes which you can use to create custom boxes that suit your brand. From the hardwearing corrugated cardboard, to the rustic kraft paper or cardstock as an alternative, we have options for each product you make. For an elegant touch, we have various special finishes including matte or glossy lamination, embossing or debossing for additional textures and foil stamping for luxurious look while spot UV coating will emphasize on some specific elements. With die-cutting facilities in place, one has even greater freedom of creating unique presentations through making custom shapes and windows. Our customized packaging options will take your brand to the next level and ensure it remains unforgettable.

UV coatings are applied as a liquid to packaging surfaces and cured using and ultraviolet light to protect, enhance and improve packaging material surfaces. The UV coating dries to create a very hard and rigid glossy or matte surface. Popularly used for shelf-ready and luxury packaging, A gloss UV coating has the ability to enhance the quality and colors of your artwork designs to create packaging bursting with shelf impact.

There are different types of Spot UV techniques, each offering unique visual and tactile effects. Here are 2 main types:

Types of Spot UV